Your One Source for Precision Machining & Components

TexelQ provides machined parts with leak testing or flow testing as a value-add service. Our skilled technicians provide in-house leak testing capabilities and ensure all parts meet the specified requirements.

Our capabilities include:

- Air decay leak test at pressures starting at 5psi with built-in poke yoke techniques.

- Flow testing for blockages

TexelQ provides various finishing options for our customers on all materials. We have a highly technical and dependable supply base for surface finishing.

- Paint Finishing- E-coat, Powder coat, Clearcoat finish

- Plating

- Shot Blasting

- Impregnation

World-Class Quality Standards

TexelQ has the quality certifications and systems in place to meet our customer expectations. TexelQ is 2018-IATF 16949 certified and follows these requirements in all products produced.

Quality Equipment & Services

TexelQ utilizes the latest quality software, gauges and CMM’s to verify the quality of all parts. In addition to CMM’s and other support equipment, TexelQ uses custom gauges that ensure the consistent repeatability of quality parts our customers expect.

Tools and services that we provide include:

- Microstructure and Destructive Testing

- Cleanliness Testing (Millipore Testing)

- Laser Scanning and Traditional CMM Inspection

- Optical Comparitors

- Surface Profilometers

- Custom Part Specific Gauging

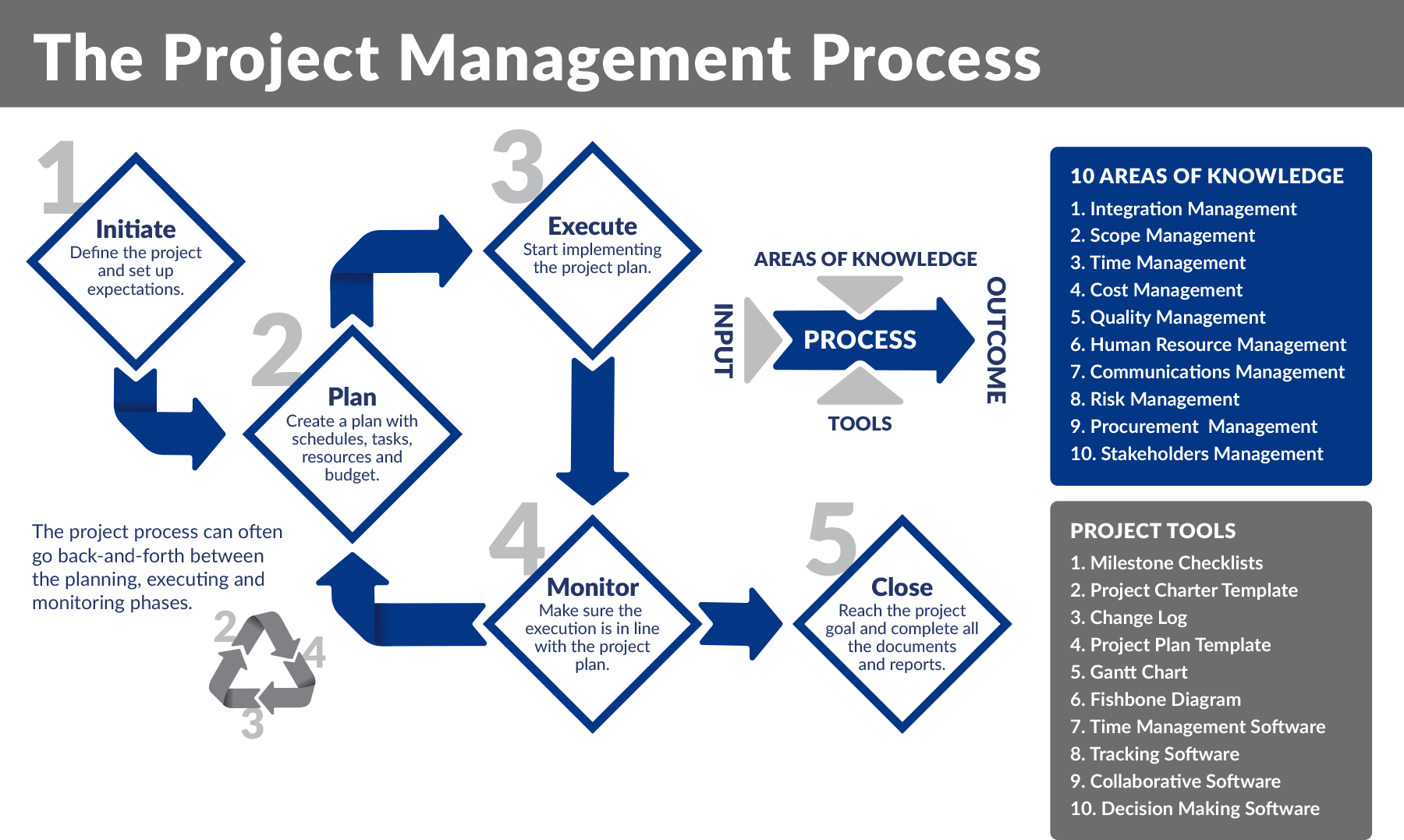

Advance Product Quality Planning (APQP)

TexelQ utilizes Advance Product Quality Planning (APQP) for all of our projects. Working in conjunction with our IATF-16949 standards and quality systems, we monitor and manage your project from purchase order to production launch. Our team will create a specific project path that keeps customers fully informed during all project phases to ensure open and clear communication and a successful launch.

TexelQ’s APQP procedures and techniques are per IATF Standards with roles & responsibilities per the AIAG Key Elements.

All requirements follow AIAG’s APQP Manuals:

- Failure Mode and Effects Analysis (FMEA)

- Statistical Process Control (SPC)

- Measurement Systems Analysis (MSA)

- Production Part Approval Process (PPAP)

Your projects will be placed in the hands of our experienced project management team. With years of automotive project management experience following the Project Management Institute (PMI) PMBOK methodology, your project is in capable hands. Combined with our extensive manufacturing, assembly and testing capabilities TexelQ is your one source for complete project management.

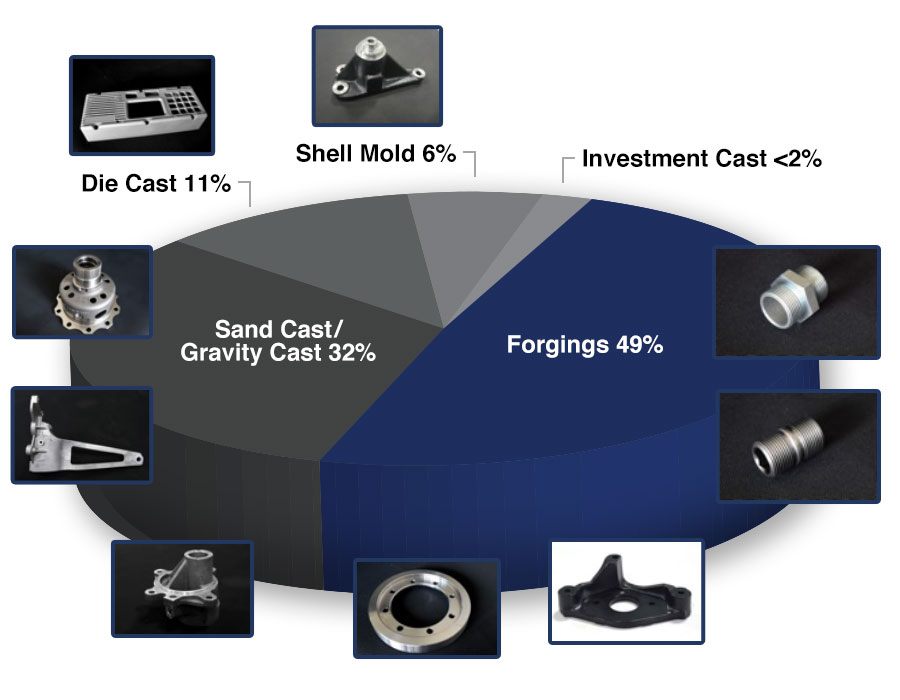

With TexelQ’s extensive supply base, we are able to provide various material options under various processing techniques.

Aluminum Process Options

- High-Pressure Die Casting

- Gravity Die Casting

- Sand Casting

- Investment Casting

Ferrous Process Options

- Grey Iron Casting

- Ductile Iron Casting

- Hot Forging

- Cold Forging

- Squeeze Casting